Industry

Whether tiny or huge

We can do that

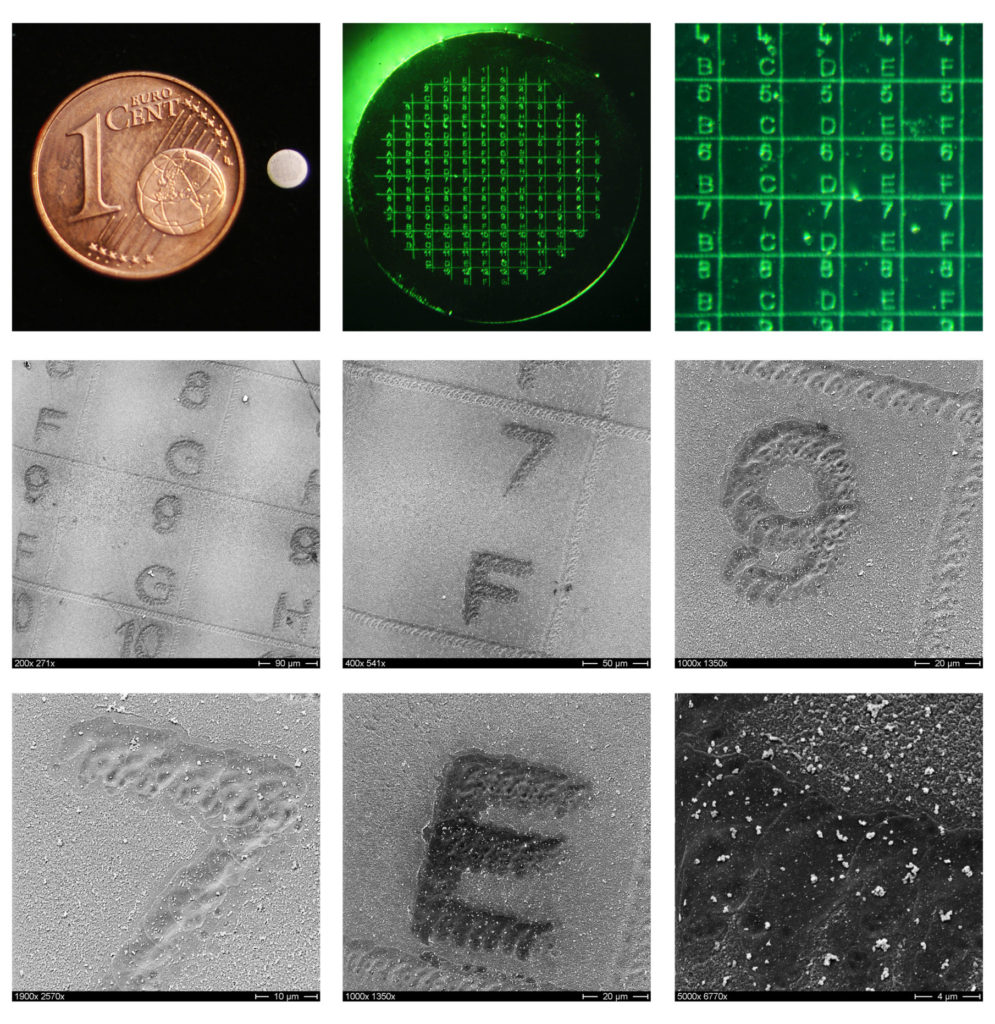

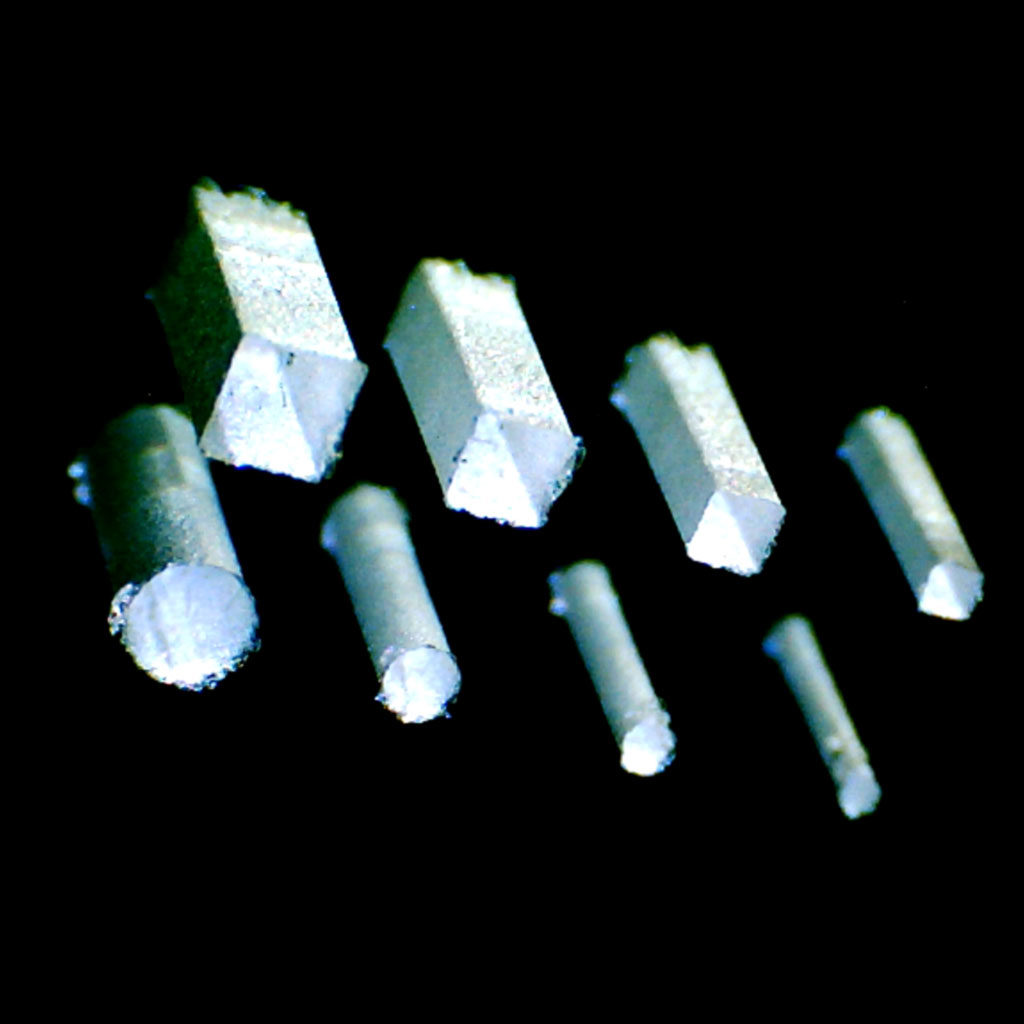

Extra small

Surface engraving on 3mm sapphire wafers magnified up to 500x.

Or extra large

The German constitution lasered into glass - memorial in Berlin.

Flat

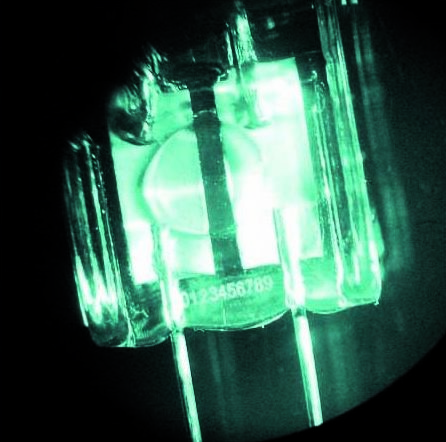

Text and data matrix code in an 8 mm glass

Serial number on halogen lamp

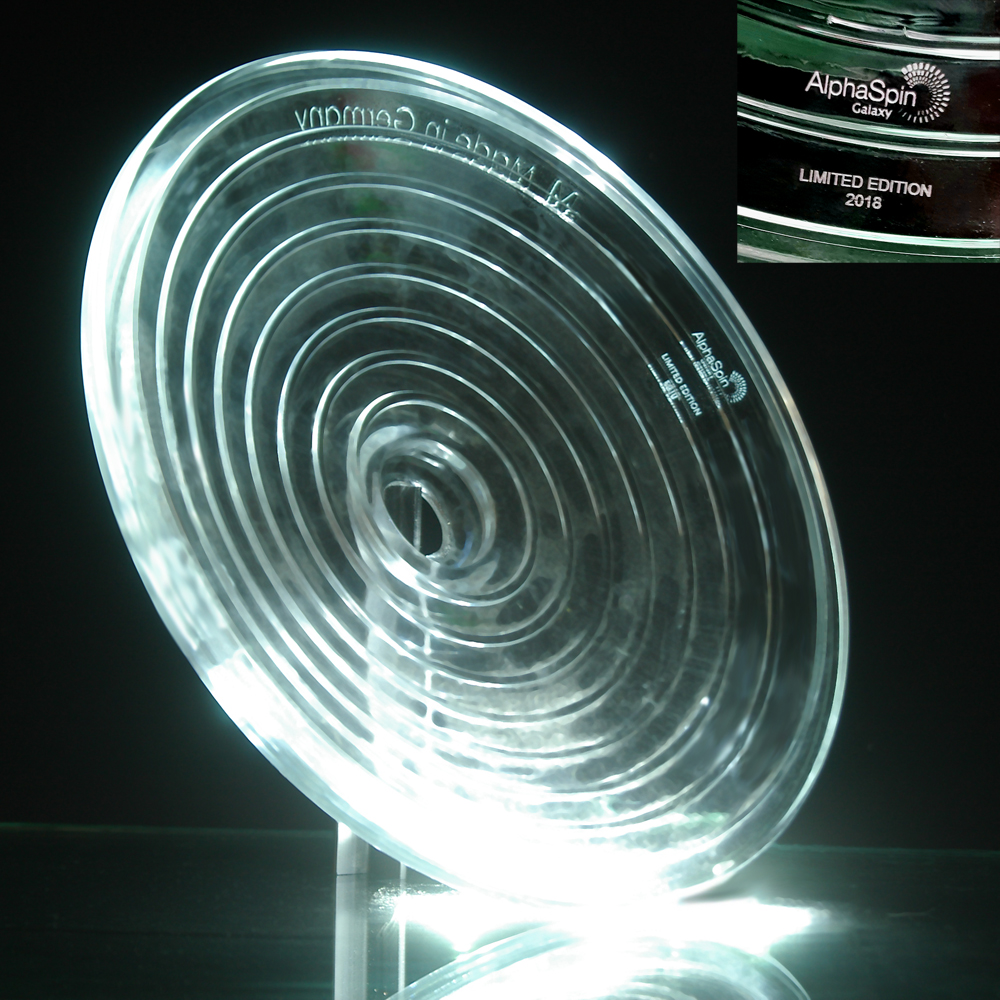

2,5D extruded

Bowl with extruded pattern

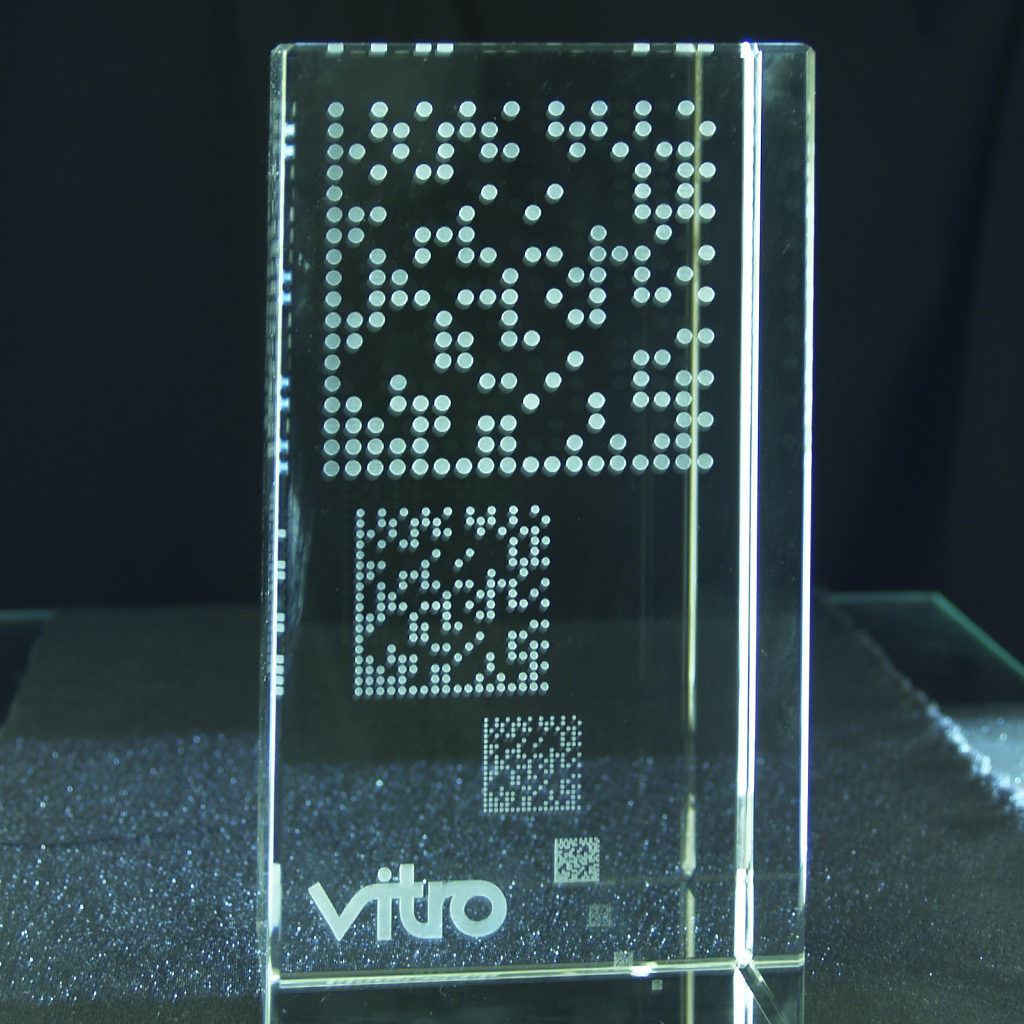

Or real 3D

3D portrait vintage model, trophy with 2D and 3D engravings

Superficial

Surface matting with integrated patterns possible

or interior engravings

In glass, sapphire, diamond and other transparent materials - we supply the system for it!

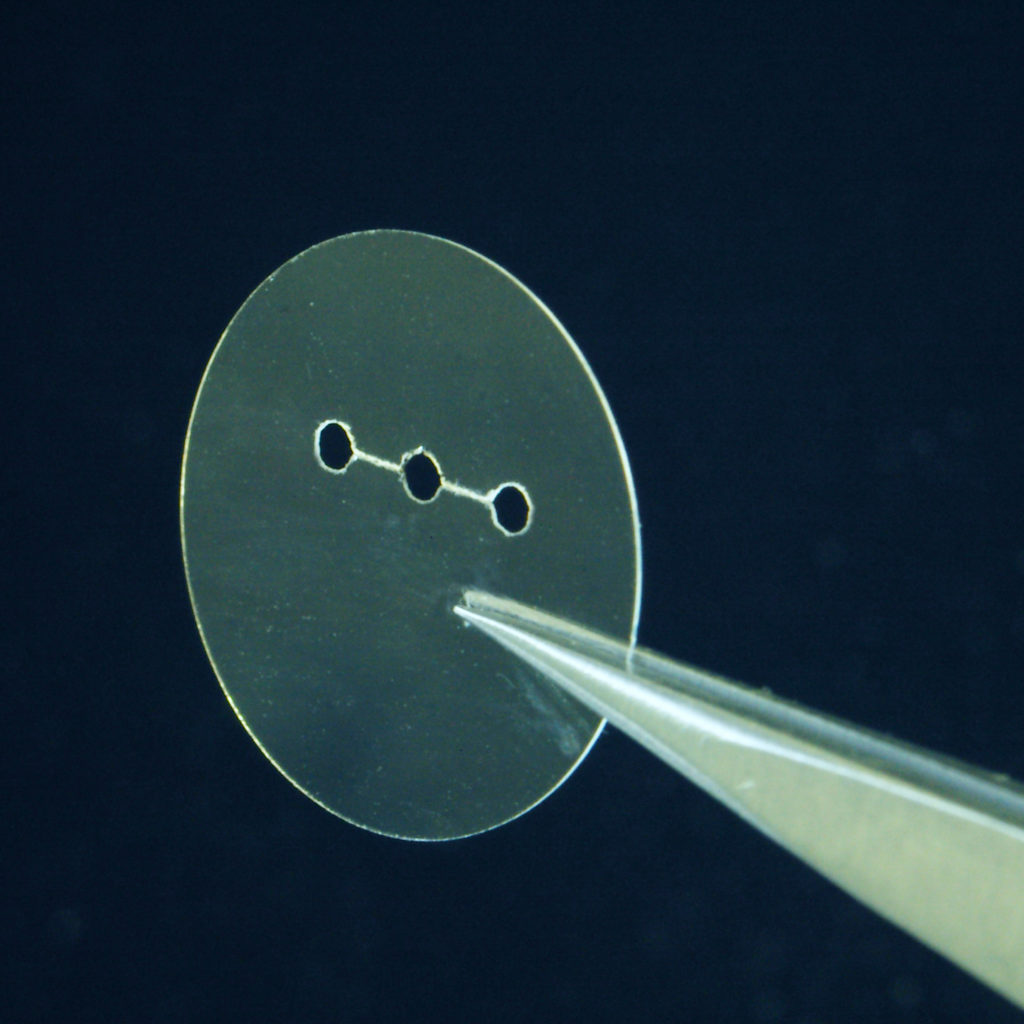

or even for drilling and cutting glass

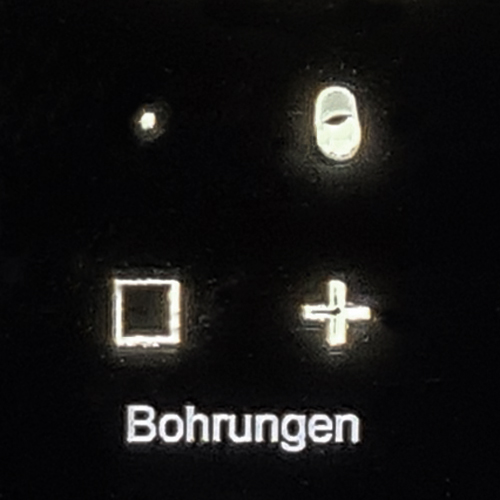

3 holes of 1mm diameter connected with a 50 micrometer-cut. Disc thickness 0.15mm.

Square and round holes in 5mm thick glass pane

Industrial use

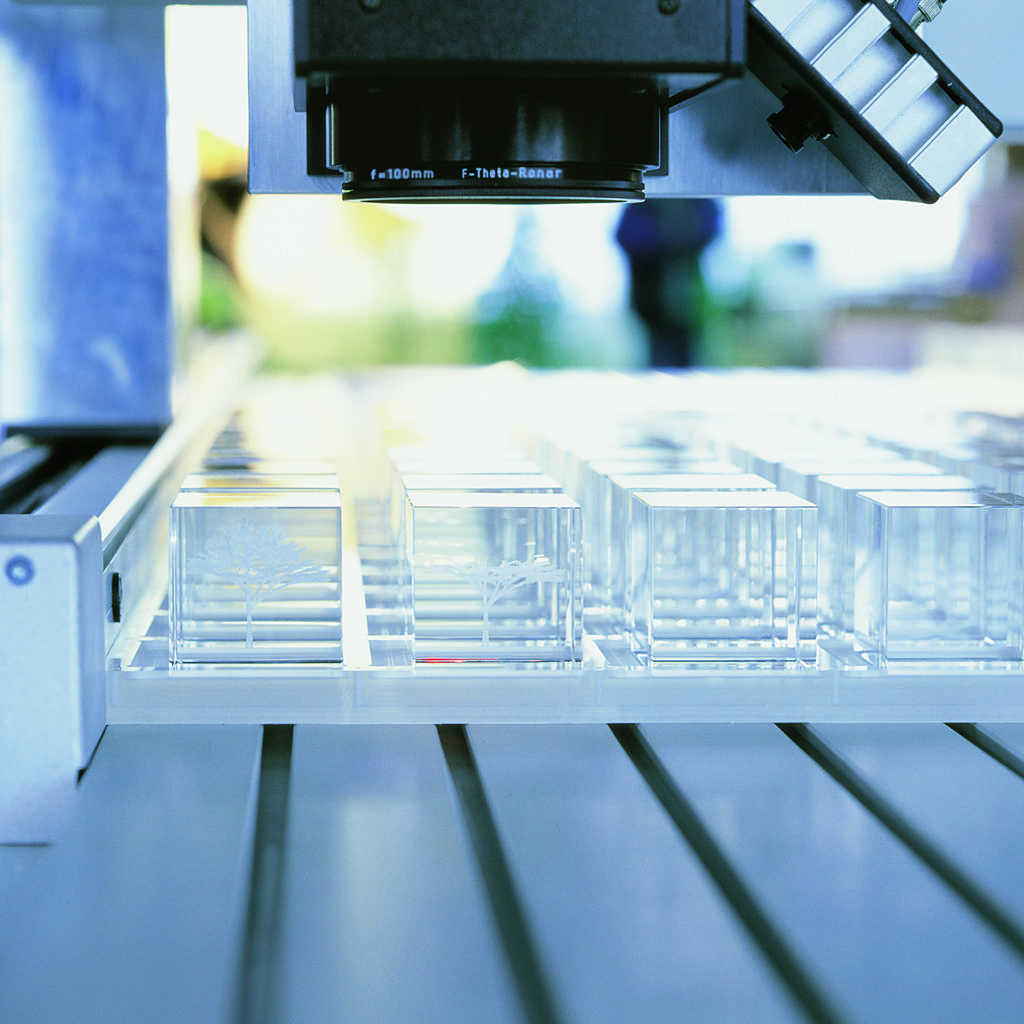

Integration into your production processes

Depending on the concept and requirements, our laser systems can be adapted to any production. Whether as a separate machine for manual assembly or as an integration in your production line.

All machines are available in laser class 1 or 4.

Industrial application

Our possible applications as transparent as possible

Light is our material. Vitro Laser Solutions UG is one of the world's leading developers, manufacturers and suppliers of laser systems for a wide variety of industrial applications. Our focus is on marking products below the surface. A surface engraving is of course also possible.

The unique selling point of the interior engraving is that the material is written on the inside. The result is an annotation that cannot be removed. Under normal conditions, subsurface engraving is non-destructive. The surface finish remains in its original condition, which is very important in medical applications or in the food industry. In other words, wherever hygiene has top priority.

Depending on the material, writing and marking is possible without destroying the surface.

This offers a wide range of opportunity both for product tracking within production and later for tracing. From logos and serial numbers to data matrix coding, everything can be engraved on a transparent material.

Most of the labeling can be done without using consumables. Intensive research work, a high level of quality awareness and continuous further development are the guarantors for an international market presence.

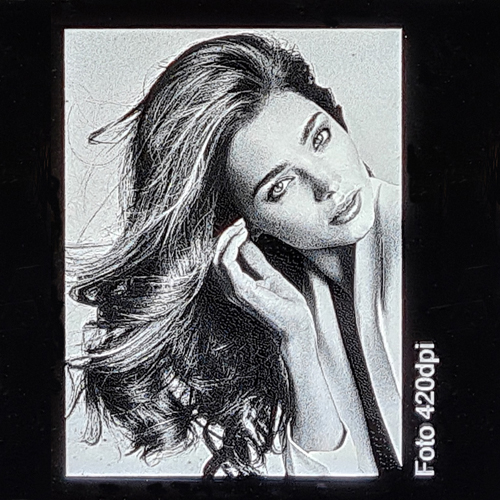

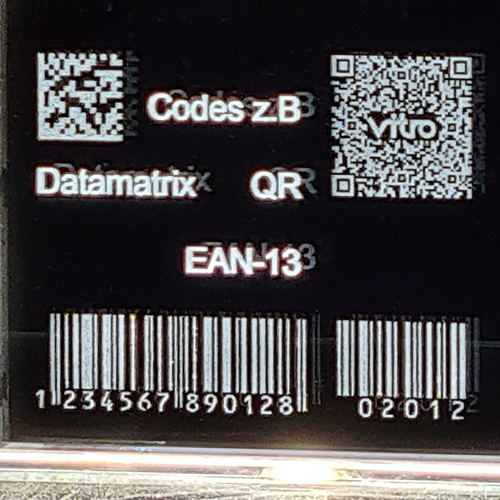

Examples of internal engraving

Sample pane 130x90x8mm

with 420dpi photo engraved on the inside,

drill holes a) 0.2mm, b) 2mm slanted c) square 3mm d) cross

example of brightness with different dot spacing

bar code, data matrix code and QR code

small 3D engravings

Red wine glasses

with brand logo

Lamp shell

26cm diameter with type engraving

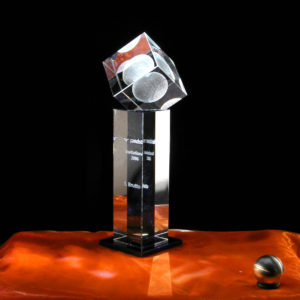

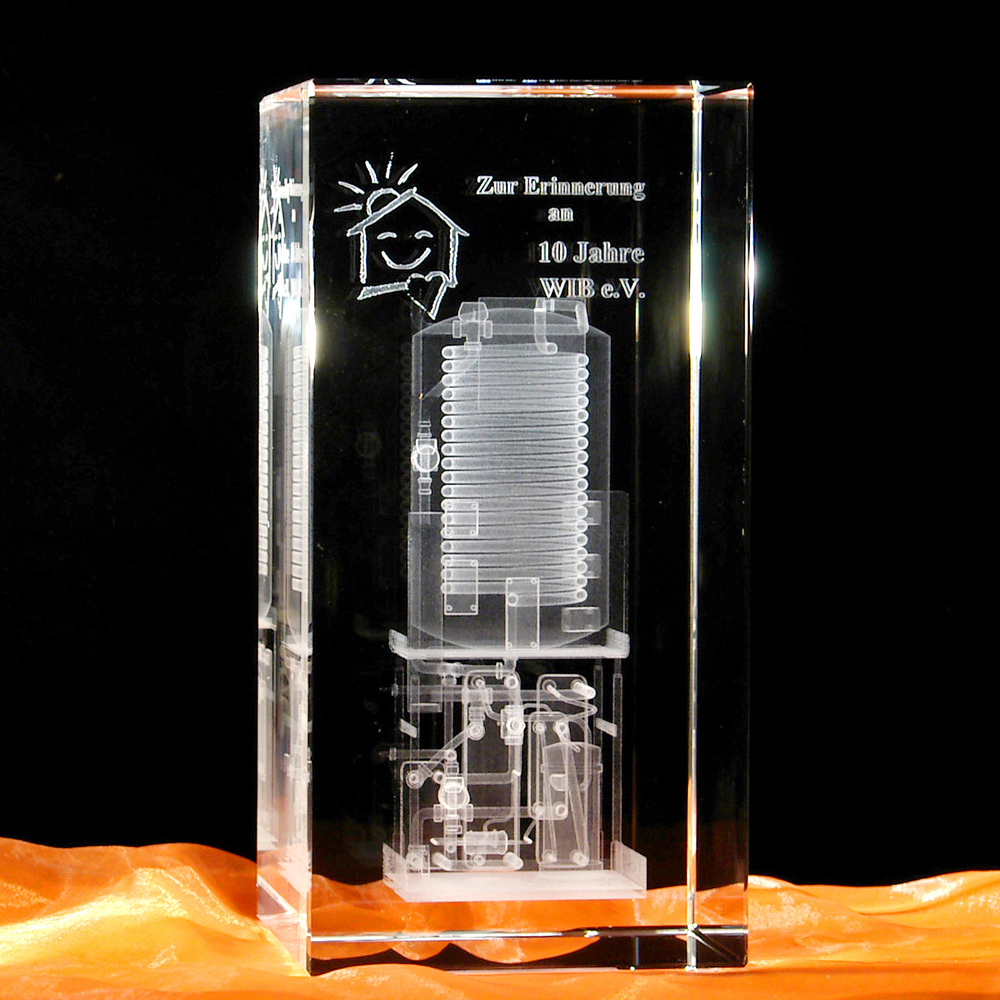

Award

with technical 3D internal engraving

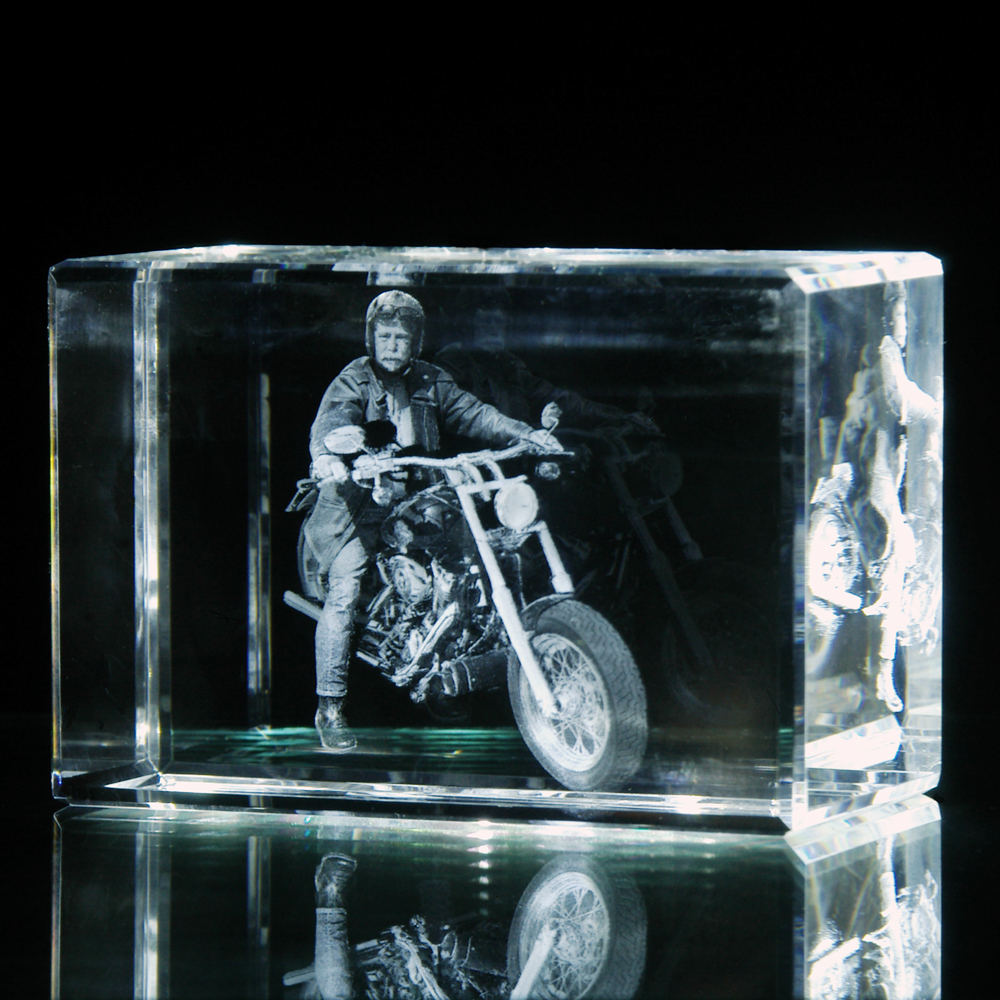

Personal gift

with 3D internal engraving created from a 2D photo

Giveaway

for combine customers

Eye catcher

with color change for trade fair appearance

Examples of surface engraving

(Surface) engraving plastic

Engraved shackle closures.

"Surfaces" is bracketed because the engraving is below the surface in the plastic. This means that the engraving cannot be felt and is protected from damage caused by cleaning processes

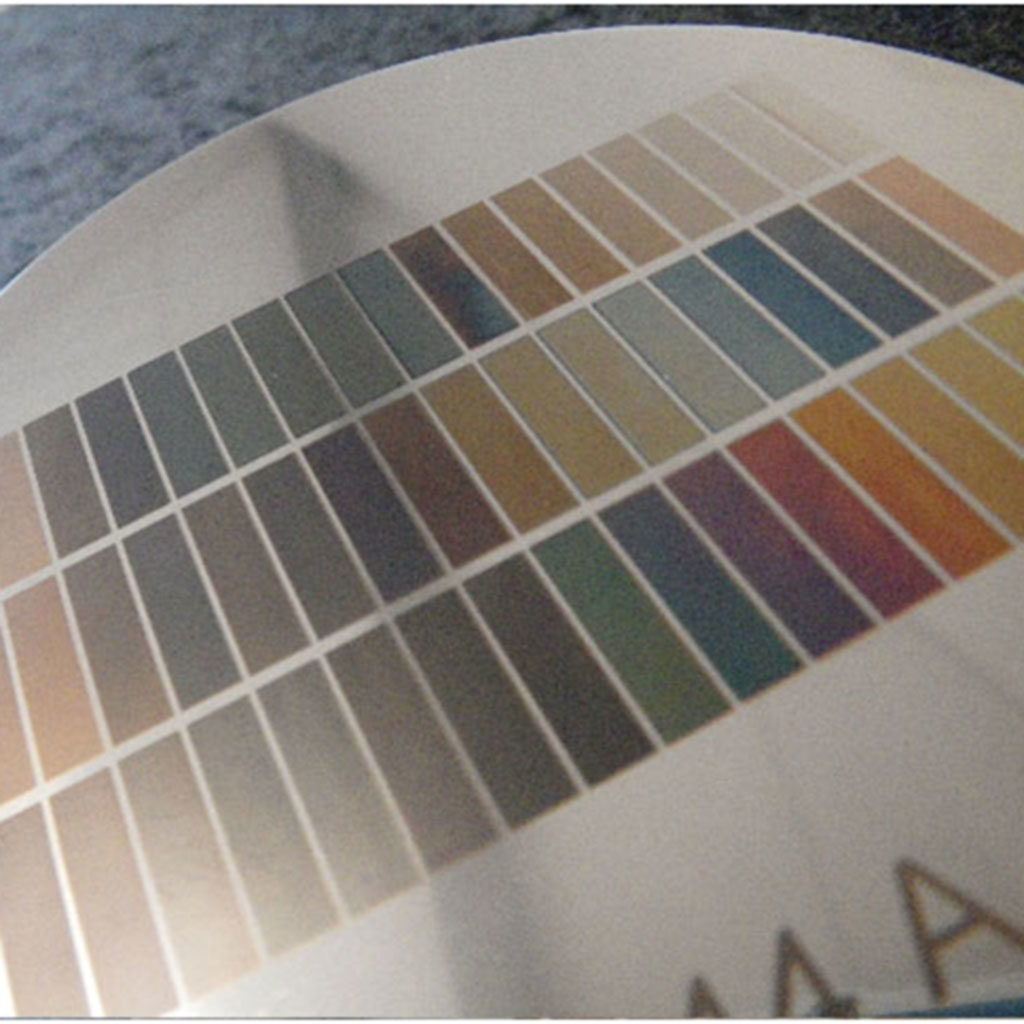

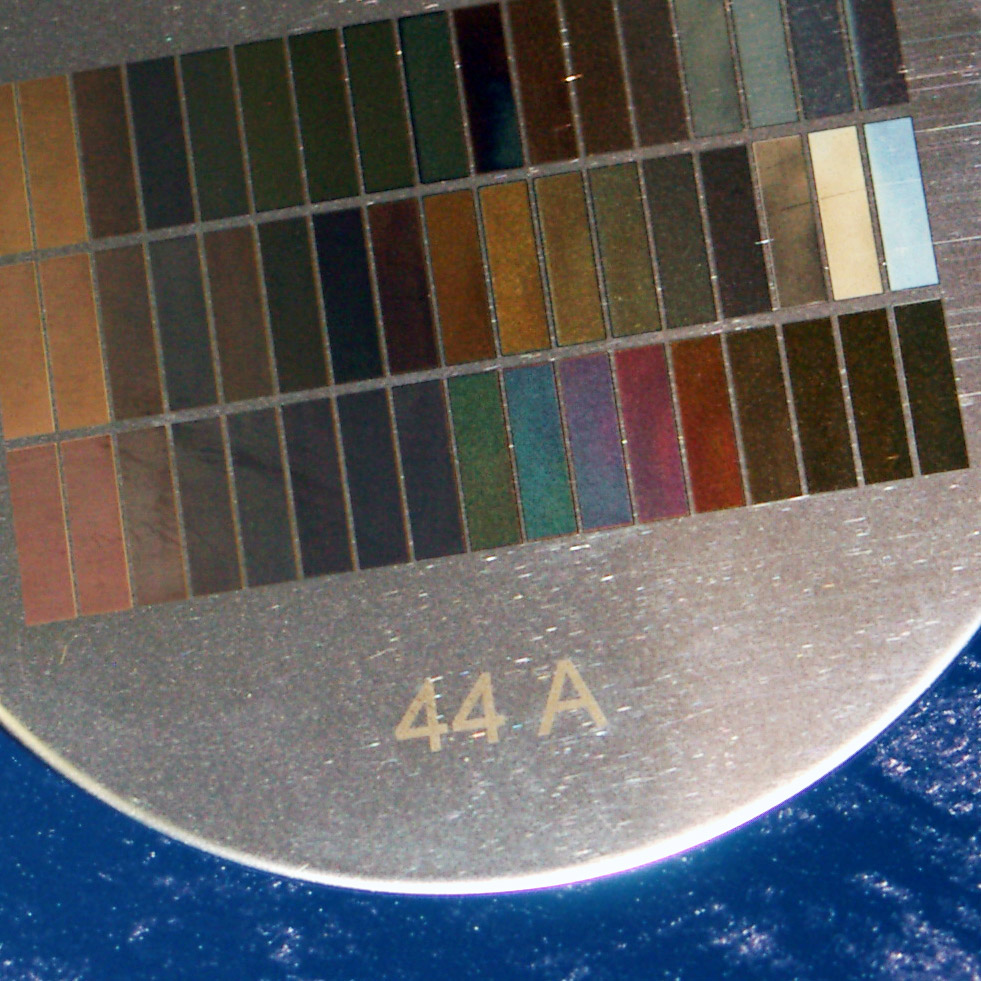

Surface engraving on aluminium

Aluminum base with surface engraving with applied glass heart with internal engraving.

Surface engraving on stainless steel

A variation of different colors

The different colors are created by different Pointcloud densities on the engraving.

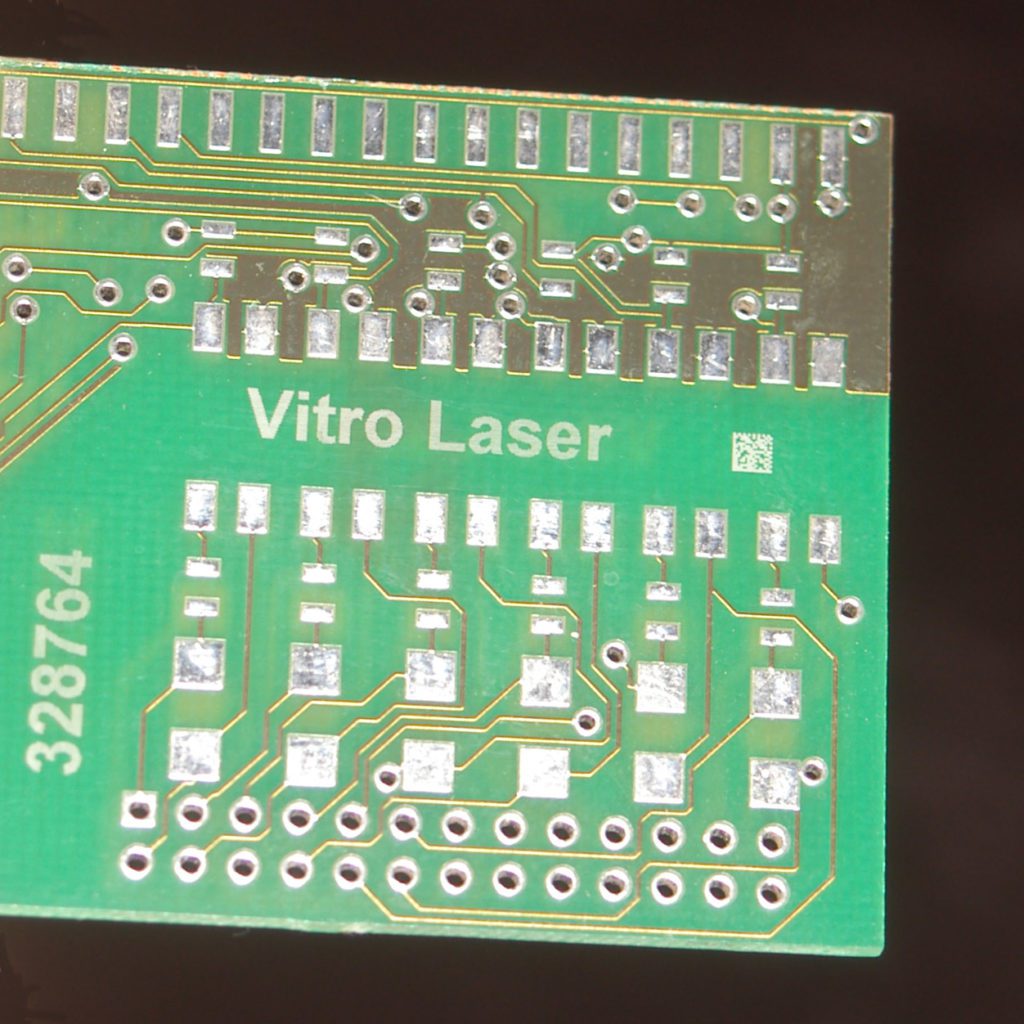

Surface engraving on circuit board

Number, text and small data matrix code engraved.

OEM Integration

We offer you several options for integrating our laser systems into your production. Together we will find the optimal solution for your application, which can consist of standard machines, the integration of our OEM version into your production line or special machine construction.

Samples

Would you like to see the engraving directly in connection with your products? Then contact us to get a sample.

A simple first draft is free of charge for you. All you have to do is pay the shipping cost. Costs can arise in the case of time-consuming test series or large quantities. However, this will be clarified with you in advance.

Materials

Basically, all materials that are transparent to the wavelength of the laser light can be engraved on the inside.