Vitrolux F

Vitrolux systems are forward-looking, reliable, economical, fast and powerful systems. They are characterized by the excellent quality of the created products. Our machines are world-leading in terms of technology.

The ideal laser system:

- Single production

- Mass productions

- Large Formats

Details about Vitrolux F

Laser technology for diverse interior engraving

Beispiel der Aufteilung der Laserfläche eines anderen Kunden. Hier können bis zu 250 Glasblöcke eingelegt werden.

Übrigens muss bei der Bestückung nicht auf Hoch- oder Querformat des Rohmaterials geachtet werden. Unsere Software dreht die Punktwolken automatisch in die korrekte Position.

Details on mass production can be found in the VitroMark.

The design of the Vitrolux F systems is the same as that of the Vitrolux E systems, with the exception of the side-closing doors on machines with a closed work area. That is why we are showing individual mass production here on Vitrolux F systems in 24/7 operation. Please note that operation with open doors corresponds to laser class 4 and therefore suitable protective goggles must be worn by the employees. In day-to-day operation, finished products are constantly exchanged for new ones and at the end of the working day the entire working area of the machine is loaded and production continues overnight.

Example of dividing another customer's laser area. Here can up to 250 glass blocks be inserted.

By the way, you don't have to pay attention to the portrait or landscape format of the raw material when loading. Our software automatically rotates the point clouds into the correct position.

Details on mass production can be found in the VitroMark.

The design of the Vitrolux F systems is the same as that of the Vitrolux E systems, with the exception of the side-closing doors on machines with a closed work area. That is why we are showing individual mass production here on Vitrolux F systems in 24/7 operation. Please note that operation with open doors corresponds to laser class 4 and therefore suitable protective goggles must be worn by the employees. In day-to-day operation, finished products are constantly exchanged for new ones and at the end of the working day the entire working area of the machine is loaded and production continues overnight.

The design of the Vitrolux F systems is the same as that of the Vitrolux E systems, with the exception of the side-closing doors on machines with a closed work area. That is why we are showing individual mass production here on Vitrolux F systems in 24/7 operation. Please note that operation with open doors corresponds to laser class 4 and therefore suitable protective goggles must be worn by the employees. In day-to-day operation, finished products are constantly exchanged for new ones and at the end of the working day the entire working area of the machine is loaded and production continues overnight.

Example of dividing another customer's laser area. Here can up to 250 glass blocks be inserted.

By the way, you don't have to pay attention to the portrait or landscape format of the raw material when loading. Our software automatically rotates the point clouds into the correct position.

Details on mass production can be found in the VitroMark.

Technical specifications

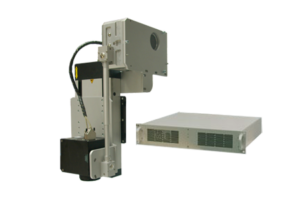

Vitrolux F

Technical specifications

Laser:

Diode-pumped, air-cooled Nd:YV0₄ laser, wavelength 532nm (1064nm / 355nm)*

Laser frequency:

4 KHz ( -8kHz)*

Optics:

High-performance optics telecentric f= 108 (170)*

Machine:

Laser according to safety class 4 or as an option with hood safety class 1

Software / Hardware:

System control via Vitro VitroMark software

The software is pre-installed on the system as standard and can be used immediately

Available Software to create Pointclouds

Vitro Voxelworx for 3D objects with texture

Vitro 2D Pro for flat images with perfect shading and multiple layers

VitroRhinoTools for technical 3D objects with differently defined point densities

Power Supply

230V/AC, 50-60 Hz

Size of the Machine

"S" 2220 x 2430 x 1600 mm (WxHxD), weight approx. 540 kg

"M" 3220 x 2430 x 1600 mm (WxHxD), weight approx. 610 kg

"L" 2720 x 3750 x 1600 mm (WxHxD), weight approx. 680 kg

Laser table:

„S“ 1750 x 2250 mm (X-Y)

„M“ 2750 x 2250 mm (X-Y)

„L“ 2250 x 3250 mm (X-Y)

Laser Room:

„S“ 1500 x 1700 x 95 mm (125)* (X-Y-Z)

„M“ 2500 x 1700x 95 mm (125)* (X-Y-Z)

„L“ 1700 x 3000 x 95 mm (125)* (X-Y-Z)

Dimensions of the laser area only apply to class 4 machines!

()* optionally available versions

Laser frequency

The engraving speed at different laser frequencies

See for yourself the progress of the engraving in direct comparison. The time required and the corresponding average number of engraved points per minute are displayed at the end of each engraving.

Matching Videos

Easily explained

Videos about our software and useful How To's about our machines.