Contract manufacturing

Contract manufacturing

Ready for your production

Whether for industry or our 3D shop customers - you have a large order but not enough capacity for it? We can handle the production or put you in touch with one of our customers. You have an idea for a laser engraving, but don't know if it´s possible? We find out!replica brietling aaaaa clone do replica magic rolex review

Examples Contract Manufacturing

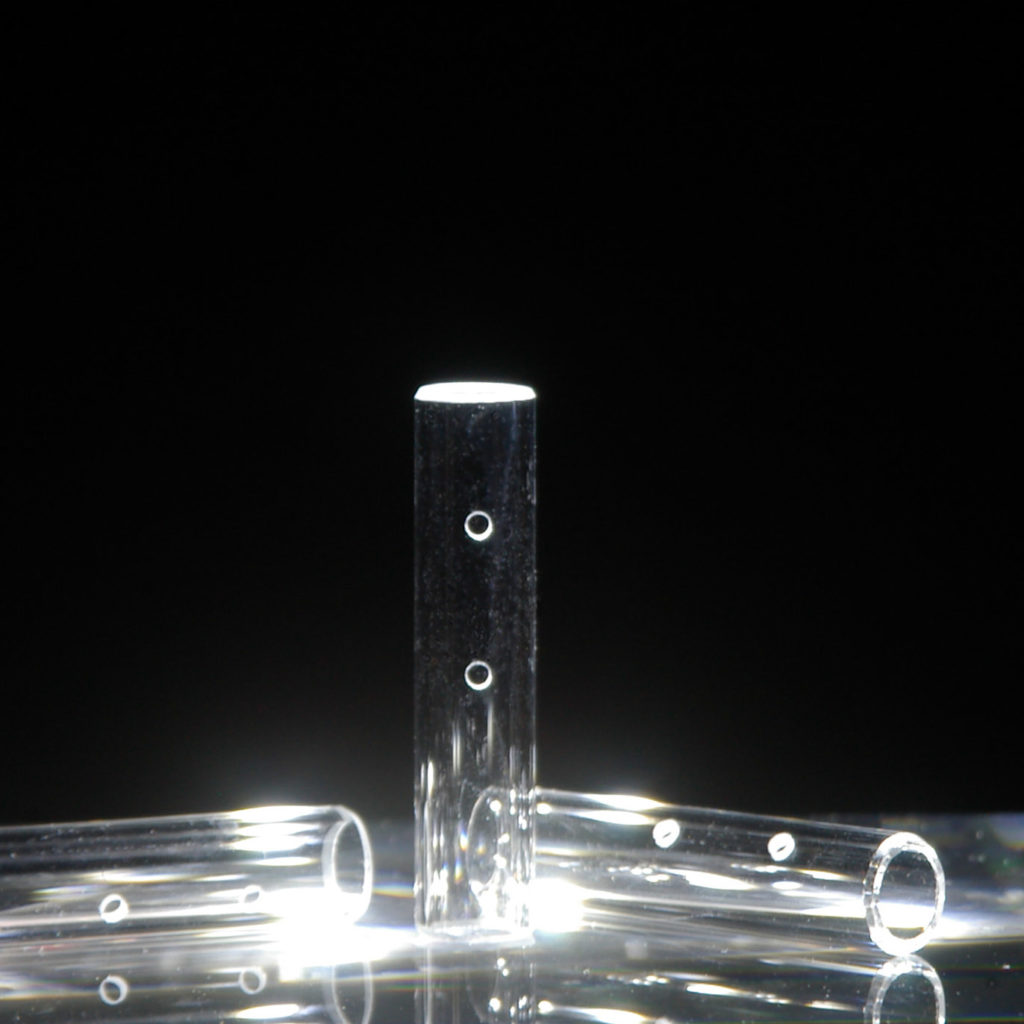

Test sample for ampoule production

Glass tubes with drillings

2 holes with a diameter of 1.6mm in glass tubes with an outer diameter of 8mm. Wall thickness of the tubes 1mm.

feasibility study

Wafers with 150mm diameter and 1.7mm thickness.

Engraved inside with fonts from 1mm high, various bar and QR codes as well as rotated codes.

The advantage of internal engraving is the dust-free labeling in clean rooms.

Test sample for syringe production

Defined cut-outs at various points on the finger rest and sample/serial number engraved on the inside of the glass body.

Glass drinking straws with internal engraving

Company logos, names, even photos with a resolution of 1,000 dpi are possible!